Two terms dominate the low-rise metal–building market, yet they’re often lumped together as if they were interchangeable:

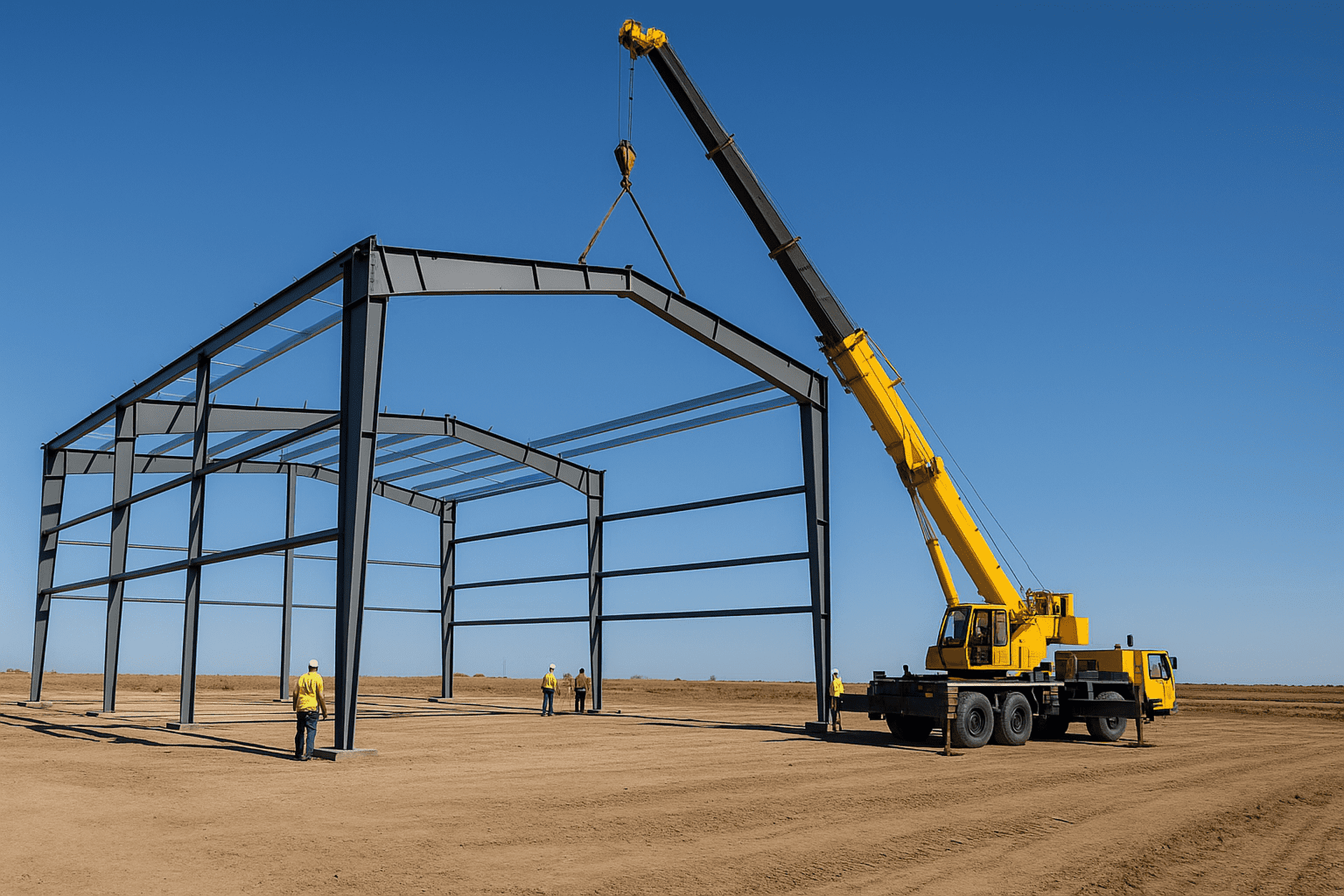

- Pre-Engineered Metal Buildings (PEMBs) — heavy, hot-rolled “red-iron” columns and rafters welded in the factory, shipped as rigid frames, and bolted up on-site.

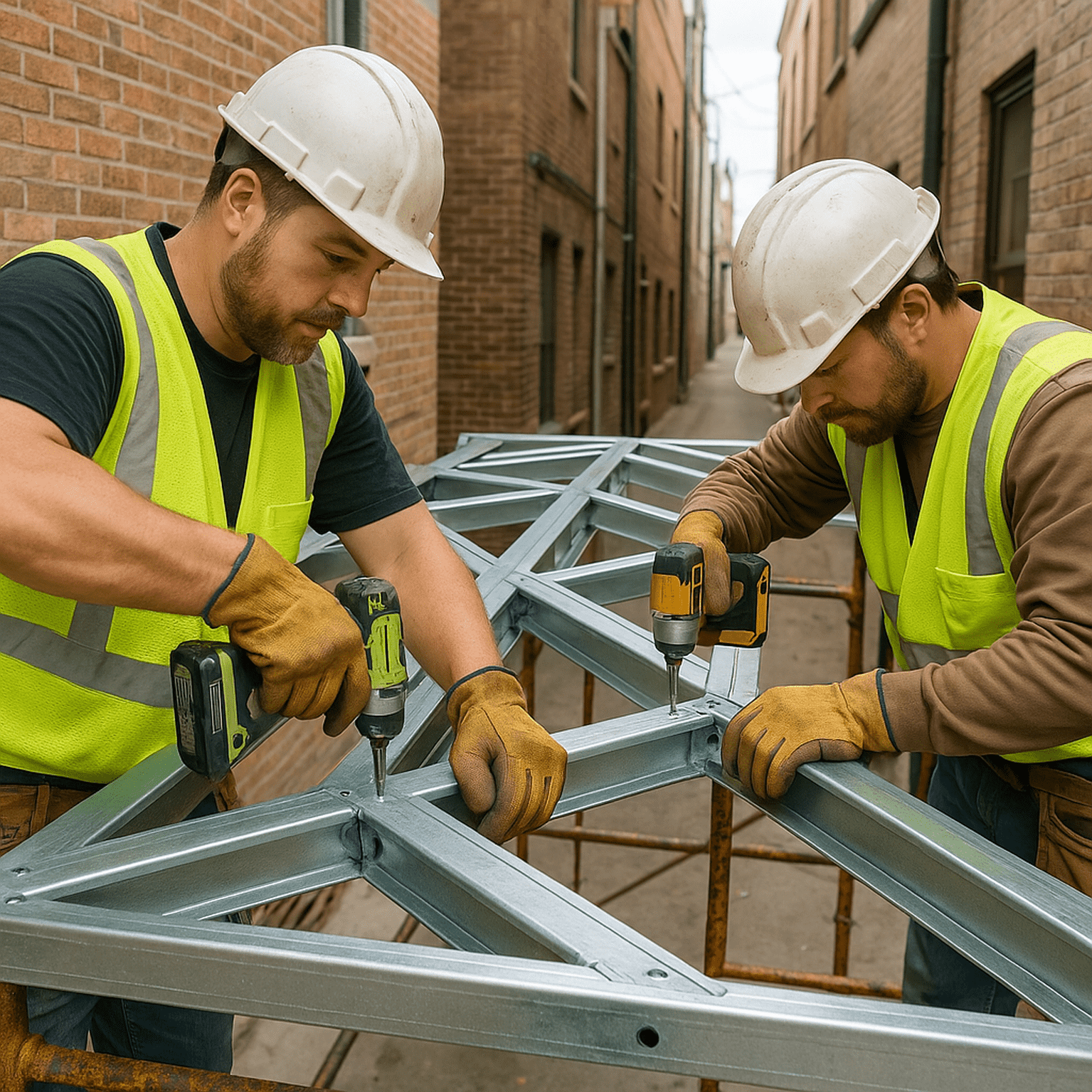

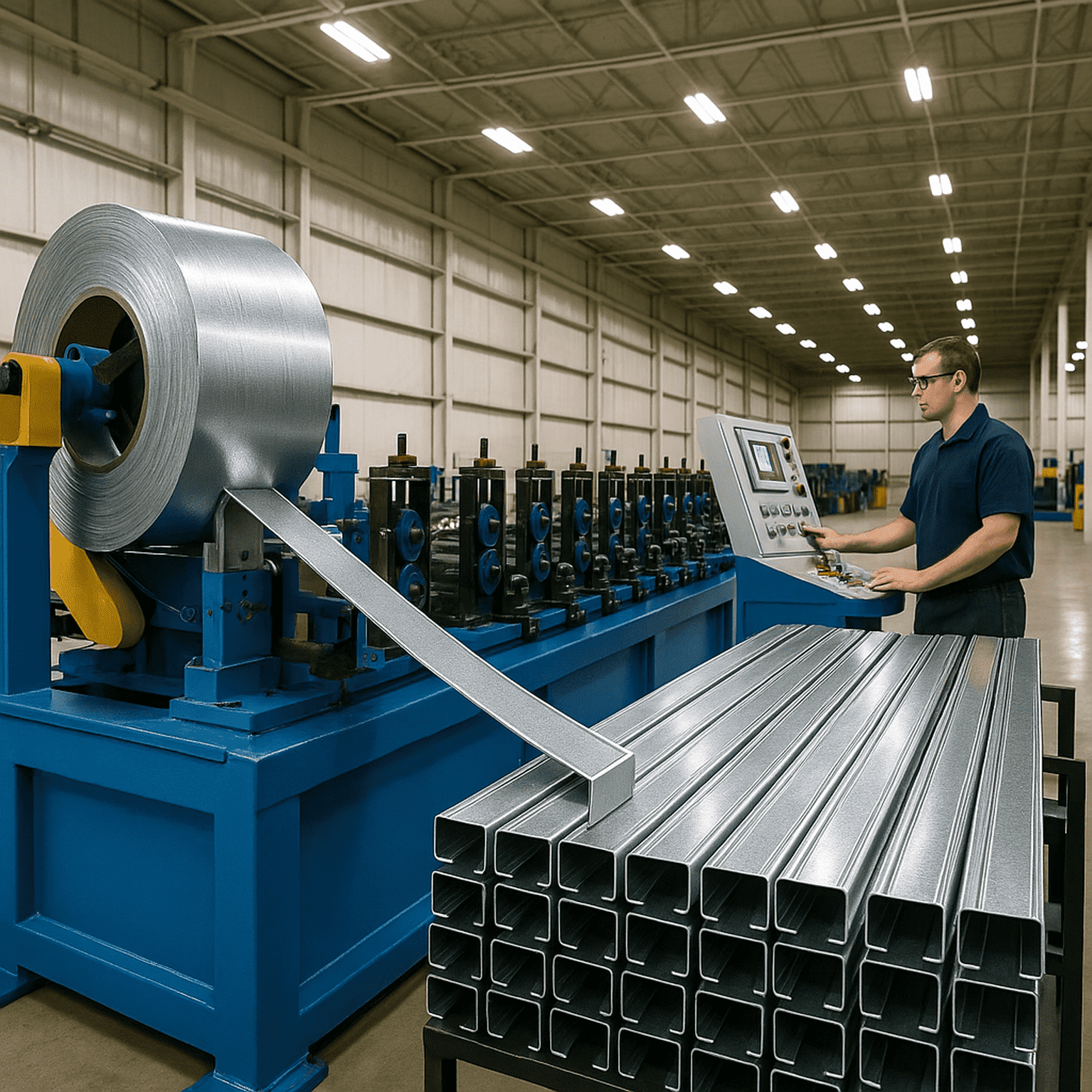

- Cold-Formed Steel (CFS) Buildings — light-gauge C- or Z-shapes roll-formed from sheet steel, screwed together into stud walls, trusses, or portal frames right on the job.

If your bids list 14-ga tapered rafters with 26-ga roof panels on one line and 16-ga C-stud trusses on the next, you’re staring at a PEMB vs. cold-formed steel decision. The wrong pick can add months to your schedule—or tens of thousands to your lifetime maintenance. The right one can shave interest, lower insurance, and even keep options open for a Phase II or Phase III expansion.

Table of Contents

- Why Two Steel Systems Exist

- Cost & Budget Reality (2025 Pricing)

- Lead Time & Job-Site Workflow

- Structural Muscle: Wind, Snow, Seismic

- Height & Eave-Height Limits

- Energy & Envelope Detailing

- Sustainability & Circular Economy

- Real-World Fit: From Mini-Storage to Mega-Warehouses

- Decision Matrix (Quick-Pick)

- Bottom Line: Frame the Future You Actually Need