Menu

STEEL AIRCRAFT HANGARS

SteelCo Buildings offers several customizable pre-engineered steel aircraft hangar to suit the needs of any aircraft owner.

Picked up a Piper Cub or other vintage plane that you want to restore? A hangar will protect it, and you, from the elements. Bought a new or used turboprop or jet aircraft? The last thing you want is to leave such an expensive craft out in the open where unauthorized personnel can have access to it.

Pre-engineered aircraft hangars are the solution. Prefabricated hangars keep your investment safe from rain, hail, windstorms or snowstorms. They protect you and your mechanics from the heat of the sun or the cold of winter while you’re working on a restoration or conducting regular maintenance. And they help prevent theft or vandalism, two real dangers no matter in what part of the country you live.

And because they’re pre-engineered, steel aircraft hangars from SteelCo Buildings can be ready in a matter of weeks to be drop-shipped across country to your location. This saves you time and money in setting up your hangar or hangars.

Metal – in particular steel – has been the building component of choice for aircraft hangars for decades. Steel is a better choice than wood for a few reasons.

Even the smallest aircraft hangar is quite large. Hangars constructed from wood will need several load-bearing supports throughout the building, which get in the way of your aircraft and other equipment! A steel hangar, on the other hand, can “clearspan” anywhere from 100 feet to 300 feet or even more, meaning there’s no need for any supports, and they can also be as high as you’d like, too. The average height for a hangar is 40 feet but we can give you a customized quote for a building taller than that if so desired.

Wooden buildings are subject to insect infestation – specifically termites – which can do a lot of damage before you even realize it. To prevent this requires yearly visits from a pest control specialist, something that isn’t needed with steel airplane hangars.

With wooden structures, there’s always the danger of fire. Steel is inflammable – it doesn’t burn. This characteristic is reflected in insurance costs for wooden versus steel airplane hangars – they are typically much lower.

When it comes to choosing a metal aircraft hangar, you have two choices – steel or aluminum. Aluminum weighs less than steel – but that means it is more easily damaged.

Steel is less expensive than aluminum. Steel does rust, which aluminum doesn’t, but that’s why SteelCo uses galvanized steel with a protective coating of paint.

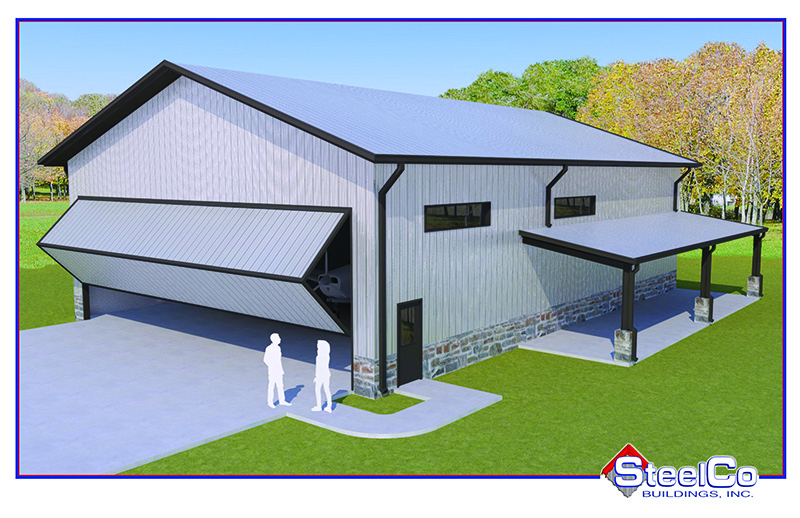

SteelCo offers customized hangar sizes and hangar designs. Hangars can be “free standing” – they’ll consist of four walls, a door system and a roof.

Hangars can be any width (we’ll give you a customized quote for anything over 200 feet wide) and any length. Hangars can be used for storing or working on aircraft, helicopters or for any type of aviation equipment.

We also offer all the door systems possible for hangars, from bi-fold doors (which raise upward) to bottom rolling doors (which slide open to either side) to allow easy ingress and egress of planes; to walk through doors along the side to allow for easy ingress and egress of people.

Windows and skylights let in available light and can help improve the usability of the hangar.

If you’d like a hangar designed with an upstairs living quarters, or office, we can do that. Simply contact us and let us know your needs.

The whole point of a hangar is to protect your aircraft from the elements. Our hangars are designed to withstand windstorms as well as heavy ice or snow on the roof.

Your local area will have its own building codes. Our pre-engineered aircraft hangars meet or exceed all business codes. We have the experience and we know what’s needed.

Depending on your location, you may or may not want your steel aircraft hangar to be insulated. If you wish your hangar to be insulation-ready, we can comply.

Depending on the complexity of your hangar design, it can range anywhere from 8 to 12 weeks to prefab every piece of equipment to our exacting specifications – and yours. Once everything is ready, it’s drop-shipped right to you. We will dropship your pre-engineered aircraft hangar(s) anywhere in the continental United States.

At SteelCo, we not only manufacture our pre-engineered steel airplane hangars but also erect them, if our clients are within 30 miles of our location.

Outside that geographic region, we will be happy to assist you in finding a qualified contractor to erect the hangar (or hangars) for you. We have a database of qualified contractors.

Having said that, our pre-engineered steel aircraft hangars are manufactured in such a way that even skilled amateurs can put them together. Because an aircraft hangar must meet a variety of codes it’s typically best for a professional contractor to do the job.

We’re here at SteelCo Buildings whenever you’re ready to talk about what you need. We’ll start from the basics to learn exactly what your requirements are and then we’ll take you step-by-step through the whole process.

Learn More About Our Aircraft Hangars

Why Choose SteelCo?

EXCELLENTBased on 66 reviews Trustindex verifies that the original source of the review is Google.

Trustindex verifies that the original source of the review is Google. Benjamin Gates2023-10-06These guys have been great to work with. I have dealt with Joseph and Brad, and they have been total professionals. Look forward to working with them again!Trustindex verifies that the original source of the review is Google.

Benjamin Gates2023-10-06These guys have been great to work with. I have dealt with Joseph and Brad, and they have been total professionals. Look forward to working with them again!Trustindex verifies that the original source of the review is Google. Toni Houtz2023-05-09Ben Childers went above and beyond helping me design and quote storage buildings. With guys like Ben Childers I will be coming back with follow up business. Thank You Donald B HoutzTrustindex verifies that the original source of the review is Google.

Toni Houtz2023-05-09Ben Childers went above and beyond helping me design and quote storage buildings. With guys like Ben Childers I will be coming back with follow up business. Thank You Donald B HoutzTrustindex verifies that the original source of the review is Google. tony biddle2023-02-28Clint was great to deal with, building material quality was very good. They even recommended a great 3rd party to construct the buildings for me. I would use them again.Trustindex verifies that the original source of the review is Google.

tony biddle2023-02-28Clint was great to deal with, building material quality was very good. They even recommended a great 3rd party to construct the buildings for me. I would use them again.Trustindex verifies that the original source of the review is Google. Brandon Wiggins2022-09-22I used SteelCo for my most recent building addition at our self storage facility. Clint and Brad were great to work with from start to finish. I would highly recommend them if you are in the market for a metal building.Trustindex verifies that the original source of the review is Google.

Brandon Wiggins2022-09-22I used SteelCo for my most recent building addition at our self storage facility. Clint and Brad were great to work with from start to finish. I would highly recommend them if you are in the market for a metal building.Trustindex verifies that the original source of the review is Google. michael johnson2022-03-29Had a project I was working on and contacted Clint Neely. Although it wasn't a huge project, he was very helpful. Within 24 hours I had a price, and he came and met me later that day to sign the order......In less than a week, materials were dropped, and work has begun. Couldn't be happier with Steelco or with Clint. Thanks!Trustindex verifies that the original source of the review is Google.

michael johnson2022-03-29Had a project I was working on and contacted Clint Neely. Although it wasn't a huge project, he was very helpful. Within 24 hours I had a price, and he came and met me later that day to sign the order......In less than a week, materials were dropped, and work has begun. Couldn't be happier with Steelco or with Clint. Thanks!Trustindex verifies that the original source of the review is Google. Mx8 Mx82022-03-28Buiding will be delivered in a few weeks. So far Steel co buildings has been very helpful, always up to date on what's going on. Never had a problem getting a hold of anyone.Trustindex verifies that the original source of the review is Google.

Mx8 Mx82022-03-28Buiding will be delivered in a few weeks. So far Steel co buildings has been very helpful, always up to date on what's going on. Never had a problem getting a hold of anyone.Trustindex verifies that the original source of the review is Google. Michelle Wilkerson2022-03-22Clint Neely was very helpful and the entire team is professional. I highly recommend the Steelco team for any industrial buildings you may needTrustindex verifies that the original source of the review is Google.

Michelle Wilkerson2022-03-22Clint Neely was very helpful and the entire team is professional. I highly recommend the Steelco team for any industrial buildings you may needTrustindex verifies that the original source of the review is Google. Joey Ayash2022-03-01I looked along and hard for a steel building supplier turns out steelco was very close and I gave brad and Ben a call, they took care of everything including all the changes and extras for my building! Great experience from start to finish ! I'll be a repeat customer! Thanks again Brad and Ben and all the steelco employees that made my building !Trustindex verifies that the original source of the review is Google.

Joey Ayash2022-03-01I looked along and hard for a steel building supplier turns out steelco was very close and I gave brad and Ben a call, they took care of everything including all the changes and extras for my building! Great experience from start to finish ! I'll be a repeat customer! Thanks again Brad and Ben and all the steelco employees that made my building !Trustindex verifies that the original source of the review is Google. Jennifer Hutchins2022-02-28I would highly recommend SteelCo Buildings and especially Clint Neely. He was very responsive and knowledgeable and the whole experience with Clint was unbelievable. Wish more companies had people like Clint working for them. Super excited to enjoy our lake house this summer. Thank you SteelCo and Clint for an amazing experience. HIGHLY RECOMMEND THIS COMPANY!!

Jennifer Hutchins2022-02-28I would highly recommend SteelCo Buildings and especially Clint Neely. He was very responsive and knowledgeable and the whole experience with Clint was unbelievable. Wish more companies had people like Clint working for them. Super excited to enjoy our lake house this summer. Thank you SteelCo and Clint for an amazing experience. HIGHLY RECOMMEND THIS COMPANY!!

SteelCo Buildings Inc.

8460 Dr MLK Jr Ave, Suite 102

Covington, GA 30014

Copyright © 2024 SteelCo Buildings Inc. All Rights Reserved

Disclaimer | Privacy Policy | Terms & Conditions